- Home

- Boat Building

- Restoration

- Planking

- Sealants

- Hull Fittings

- Bottom Replacement

Vintage Wood Boat Bottom Replacement

There

comes a time with every vintage wood boat when normal bottom

maintenance is no

longer sufficient to keep the water out.

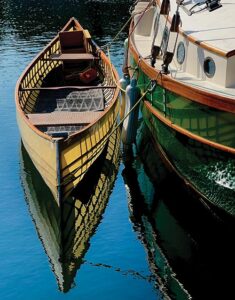

Classic wooden runabouts can even be improved with the use of modern materials such as waterproof membrains, plywood and bedding compounds without detracting from their style or value.

Vintage wood boat Problems.

Many of the problems with vintage wood boat motorboats and runabouts

stem from planking a typical hard chine, concave bottom.

While this bottom profile is ideal for fast motoring, it isn’t

the ideal shape for wooden planks.

Fast motoring also means that the most concave area takes most of the

pounding.

As a result fasteners

become

loosened, broken, or bent, planks crack along the fastener lines,

frames

can crack

and chines get pushed out.

And that is as well as the rot which comes from water settling the

bilges and the transom area.

Then there are those boats where the layer of canvas between the inner

and outer planking is beginning to rot.

Wood is a wonderful material and there is nothing to compare with a

vintage wooed boat.

However, wood is always moving as it expands and contracts with the

changes in temperature and moisture levels.

Traditional boat building methods allowed for this movement as well as

hull flexing.

Unfortunately, many of these boats have been damaged by repairs.

In some cases over caulking has put too much strain on the fastenings and frames, and all too often hard inflexible epoxy products have been used.

affiliate linksPlanked Repair.

There comes a time when ‘fixes’ will no longer be sufficient to restore your vintage wood boat and make her water tight.

And the ‘fixes can sometimes result in even worse problems.

This is when that leaky vintage wood boat bottom will have to be replaced.

So bite the bullet and remove the old bottom.

You will now be able to see and repair any damaged frames or chines and tighten or replace the frame fastenings and don’t forget to give them a good sealing with paint.

Once that is done, before re-planking give her bottom a lining of either 4mm marine grade plywood or a flexible waterproof membrain.

Use a flexible bedding compound such as 3M 5200 and fasten to the frames with either small silicon bronze gripfast nails or stainless staples.

Now the planking can be replaced with a good layer of flexible bedding compound between it and the plywood. or the membrain.

If you have been able to save most of the original planking you may need to plane it down to compensate for the thickness of the plywood.

But even if you are planing to replace all the planking keep the old ones to use as templates.

Bed each plank as you fit it and use silicon bronze fasteners.

Excess bedding can be allowed to ooze up between the planks then scraped off and smoothed.

If you replace the inner planking with plywood it should be painted before fitting and it can also be scored so that it looks like the original planking.

This process effectively produces a double planked bottom with the added advantage of the unidirectional strength of the plywood.

Don’t forget to check and if necessary to repair or replace the lower chine and lower transom planks.

affiliate linksCold moulded Bottom.

An alternative to the planked bottom would be to replace it completely with a cold molded plywood one.

Purists might argue that this is perhaps too far from the original vintage wood boat.

However, it will give her an incredibly strong, seamless bottom.

This process is similar to that above, except that instead of finishing off with a layer of solid timber planks several layers of plywood are laminated together using that flexible bedding compound and fastened to the frames using silicon bronze fasteners.

Use three to five layers of 4mm marine plywood depending on the thickness of the original bottom.

As with the previous method all the structural elements should be inspected and repaired before replacing the bottom with new silicon bronze fasteners.

affiliate linksFinishing.

It should go without saying that while you have her stripped down all those other underwater components such as rudder assemblies, propeller shafts etc should be checked and re-seated.

Once the bedding compound has properly cured the bottom can then be sealed, primed, and painted.

This is not an easy fix, it is a major undertaking which will require a lot of hard, messy, time consuming work.

However, once done your vintage wood boat will have a bottom that will not leak for a long time to come.

And it will have the added benefit that she will not have to ‘take up’ every time you launch her.

Previous posts

See What Others Have Posted

Replacing the bottom of the Trojan cruiser; by Dave S

I replaced a rotten bottom on my 32' double plank cruiser 22 years ago.

The job took me 5 months.

If you plan on such a job like this you only …

1960 Trojan Cabin Cruiser in need of a new Bottom.

I have a 1960 Trojan Cabin Cruiser due to rot I have to replace the bottom!

I was thinking about doing the whole thing with the marine plywood as I …