- Home

- Ropes and Rigs

- Rope Types

- Splicing

Splicing Three Strand Rope.

Not only is splicing a satisfying art, making up your own dock lines will save you money, why pay someone to do something that is so easy.

And you can tailor those lines to suit your own boat rather than having to buy stock lengths.

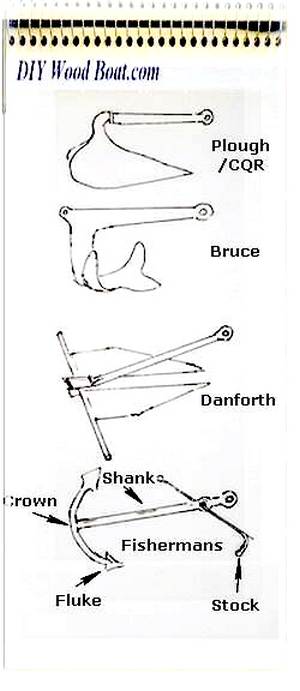

Once you have mastered the basic technique there are numerous other uses such as anchor lines that require an eye with a metal thimble to protect the line from chafe, rope ends that need tidying or lines that need joining.

Where a permanent join or eye is required in a line, splicing will not only look much neater and more seaman-like than a knot but will also be much stronger.

Tools

You

only need a few basic tools, a sharp knife with the emphases on ‘sharp’

so the ends can be cut cleanly and a marlinspike or fid to separate the

rope strands.

The marlinspike is a round pointed spike used to lift and separate the

individual strands.

A Swedish Fid will do the same thing with the advantage that the ‘hollow’ side makes it much easier to thread the strand to be tucked.

When

working with synthetic ropes a

heated rope cutter will hep seal

the ends and prevent unravelling, a cigarette lighter can be used but

this will have a tendency to blacken the ends if you are not careful.

On the other hand some tape such as the cheap electrical type is fine

for temporarily holding the yarns to stop the ends unravelling.

And as I will explain later I also use my ‘Handy-Stitcher’ and some whipping twine.

affiliate linksThe Basic Technique

It is always best to use good quality rope

on board and the better the

rope, the easier it is to splice.

The strength of any splicing will increase with the number and

tightness of the ‘tucks’.

However,

the first four or five are the most important, any subsequent ‘tucks’

will have a decreasing effect on the overall strength.

The first thing to do is to slice the rope end cleanly with

that

sharp knife, if you wrap the end with tape first then cut through the

middle of the tape it will hold the strands until you are ready to

unravel them.

Decide how much of the bitter end will be needed to give the required

number of ‘tucks’.

You should allow a length of three times the rope diameter for each

tuck, so for

five tucks allow a length of approximately 15 times the rope diameter.

I

am very much the amateur at this, I only do it on my own ropes, so

not very often.

The trick I use to get started without the rope unravelling

too far is to tie a couple of whipping turns at the point where I want

the splice to start.

And I anchor the whipping by using my ‘Handy Stitcher’ to push one end

of the twine through the rope.

Then the rope can be un-laid as far as the whipping.

The ends of the strands now need to be either wrapped with tape or heated with a flame to prevent the strands from fraying.

Having the ends of each strand wrapped or heat sealed neatly

and

preferably with a point will make it easer to tread them through each

tuck.

When you begin ‘tucking’ try to keep the twist in each strand so it

will lie neatly.

The following is how I, as a right- handed person proceed, if you are

left-handed

you may find it easier to do it upside down, as it were.

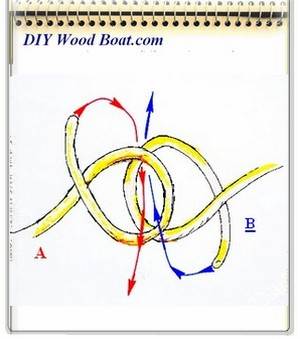

So, right-handers begin with the un-laid

end towards you and the

standing part pointing away and remember all the ‘tucks’ will

go from right to left.

Now fan out the un-laid strands.

Use the fid to lift a strand on the standing-part of the rope as close

to the whipping as possible.

Now tuck the centre one of those un-laid strands under it.

Pull this first tucked strand through firmly, not so hard as to distort

the lay of the line.

Next take the left-hand strand.

The second tuck is always the left-hand ‘un-laid strand’, tuck it under

the ‘standing-part strand’ above the one you just tucked the centre

strand under.

Pull through firmly.

Now that remaining ‘un-laid strand’, the right-hand one, this wants to

be tucked under the ‘standing-part strand’ below the one used for the

center strand.

So it is center first, then left above, then right below.

Now that you have all three ‘un-laid strands’ tucked in once, pull them

all firmly to snug them down, then the rest is easy.

Just carry on tucking those ‘un-laid strands’ in turn, so that each

strand goes under a strand on the standing part, then over the next

then under again etc.

Turn the rope anti-clockwise a third of a turn for each tuck and tuck

the strands in sequence.

When you have the desired number of tucks, pull on the rope to

stretch it and roll it between your palms to smooth it out.

Then trim off the ends of the tucked strands and the splice is finished.

If the rope is synthetic you can melt the strand ends and press them

tight to the rope.

You can if you wish finish off with a few tapering tucks.

Trim a third or so of the yarns from the tails, then continue to give these trimmed strands a few more tucks, then finish as above.

Back.

The Back or End-Splice is used as a

permanent way to prevent the bitter

end of a line from unravelling.

However, a splice does results in a thickening of the line, so if it

has to pass through a block or such like then a whipping will be the

preferred option.

As the name suggests the strands are woven back along the line.

And as this splice is merely to prevent the bitter end unravelling it doesn’t require strength, so three or four tucks will be more than sufficient.

The

only departure from the technique above is

that it requires a ‘Crown Knot’ before starting with the tucks.

For the ‘crown knot’ hold the rope with the standing end towards you

and the ‘un-laid strands’ away from you.

Then, working anti-clockwise, take any strand and pass it over its

neighbour.

Bring that neighbouring strand down across the other two.

Now take the remaining strand over the second and through the loop made

by the first.

Tighten each strand by pulling towards you so the strands now lie along

the length of the line.

This is where a couple of ‘tapered tucks’ will be of some advantage should the line ever need to be hauled through a restriction.

Books

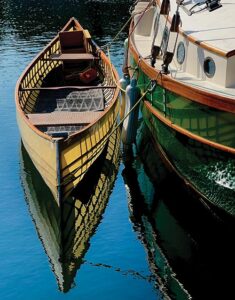

BooksEye

Tying a bowline is the quickest way to make an eye in rope.

However, for maximum strength nothing beats an eye splice.

And

with three strand rope it not only looks good but is an easy splice to

do.

You can buy lines with an eye already spliced into one end, but

naturally you have to pay for this service.

Personally I disagree with the concept of having dock lines with a

permanent eye in one end because the wear is always restricted

to that one

place on the rope.

However, when you do require a permanence loop at the end of a line,

putting in your own eye plait is a neat and easy option, especially

with

three strand rope.

Where

an eye is

subject to constant wear or chaffing such as where it is used to attach

a line to metal fitting then a thimble should be inserted in

the eye.

Again the technique is the same as above.

However, this is one instance where the start position of the plait must be really tight up to the thimble to prevent it falling out.

And it is where I find using the Handy Stitcher invaluable.

affiliate linksShort Splice

The short-splice is used to join two ropes of equal diameter and number

of strands.

weave the strands of each rope into the main portion of the other rope.

Start

by laying the strands of one rope between the strands of the other.

Make the fist set of tucks of one rope into the second rope, then

repeat for the second rope into the first.

Once the first set of tucks on each rope has been established the rest

can be done in any order.

However, as splicing increases both the diameter and stiffness of the

line the resultant join will not run through blocks and other fitting

which are the correct size for the original rope diameter.

For that reason this is unlikely to be seen on small boats

these days.

However, back and eye splices are worth the small effort not only for their strength and neatness but also as a testimony to your seaman like skills.