- Home

- Your Boats

- Rope Types

Rope Types for Boat Lines.

Boating

rope types or

lines, as us boaters prefer to call them, come in several different

types

of construction as well as sizes and materials.

It is the construction of the line as well as the material it is made from that will determine its strength and its uses.

So, when is it best to use braided lines and where would three strand be better?

And why is the type of construction material important?

Natural fibre rope has almost entirely been

replaced by modern synthetics

because of their superior strength and durability.

Save yourself money by choosing the right types for you boat.

For most of us the main types of synthetic materials used for boat ropes are nylon, Dacron, polyethylene and polypropylene.

For mooring and anchoring lines some stretch or give is beneficial but for most rigging lines on a sail boat, it is best to minimise stretch.

Many of the more expensive blends of synthetic fibres, such as Dyneema, Kevlar, Technora and Vectran used on racing sail boats are designed to minimise stretch.

But beware if you are considering upgrading, using some of these hi-tec. ropes might require replacing your deck gear.

Ropes are made by twisting the fibres, whether natural or synthetic,

into yarns

and then twisting the yarns together to form strands.

The strands are then twisted, plaited or braided together to form the line or rope.

affiliate linksThree strand

Three Strand Rope

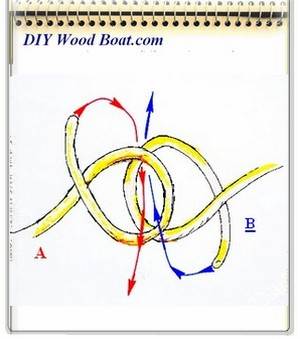

Three Strand RopeThree

strand or ‘Plain laid’ lines

can be made with the three strands twisted either to the left or the

right.

The direction of the twist determines the ‘lay’ of the rope.

However, the majority of these lines are right

laid.

These right handed laid lines can also be called hawsers and the

clockwise lay

referred to as ‘hawser laid’.

The process begins by spinning the yarns left handed into strands, then

the

strands spun right handed to make the line.

Occasionally three or more lines may be twisted together to make a large mooring cable, these will be spun left handed and referred to as ‘cable laid’.

Three strand lines with their stretchiness are fine for docking and mooring and are easy to splice.

affiliate linksPlaited line

Platted

lines are made using eight strands platted

together in pairs.

Four of the strands will have a left handed lay the other four will be

twisted

to the right.

These are then paired and plaited together.

Plaited and multi-plat rope types are ideal for mooring and anchoring due to their strength and stretch.

Braded Rope Types

Braided Rope with Parallel Core

Braided Rope with Parallel CoreBraided lines come in different construction types such as

hollow-braided,

stuffer-braided, solid-braided and double braided or braid on braid.

They are usually made by platting or braiding together groups of three

strands

to form the ‘sheath’.

A sheath is usually made up from 16 strands which encases a

‘core’.

Cores can be made up from fibres laid parallel, twisted or plaited.

Braided Rope Twisted Core

Braided Rope Twisted CoreWhere the core is plaited the line is known as braid on braid.

The most common type of braided line is double braided nylon.

Double braid, has a braided core tightly encased within a braided cover

which

in turn is encased with in a braided sheath.

This unique rope type construction provides superior strength, 50% of which comes from the core, plus abrasion protection afforded by the outer sheath.

Braid on Braid.

Braid on Braid.Used mainly for running rigging due to their low stretch and the outer cover that makes for handling comfort.

Braid on Braid

Braid on BraidIt is possible to use some of these modern ropes such as Spectra™ as an alternative to stainless steel for standing rigging.

While they provide an enormous weight advantage and can be simpler to rig, there are downsides.

There is a greater risk of chafe and UV degradation than with stainless steel.