Making Wooden Panels.

Wooden

Panels for bulkheads, chart tables and

transoms or rudders may

need to made using edge to edge

joints.

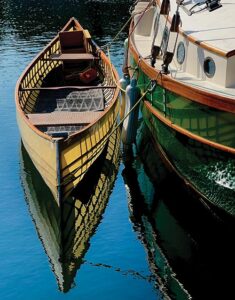

Admittedly plywood is a convenient material for making large sheets.

However, if it is to have a natural finish, varnished

or oiled plywood

will

never have the same look or feel as natural wood, nor

is it the best material for underwater situations.

These assemblies will normally be made up from narrow planks.

The first problem is to plane the edges both square and straight so they will butt together without gaps.

Planning square level planks can be made easier by clamping two or more

in the

vice and planning them back to back.

Another method is to use a ‘shooting board’.

While it is possible with care to butt joint the planks, a more stable

panel

should have some form of edge to edge joint.

Tongue and Groove is probably the most common edge to edge joint.

Panel Joints

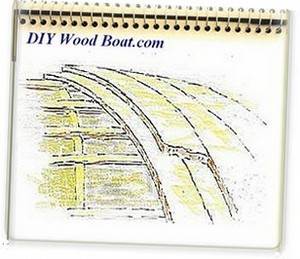

Alternating Direction of Grain

Alternating Direction of GrainThe tongues and grooves can be cut fairly simply with a Multi

Plane.

There are several other methods using dowels, biscuits, and splines.

And there are various jigs which can be bought to ensure alignment.

Long planks joined lengthwise like this have a tendency to warp and to open up at the ends of the joint.

To prevent the end of the joint opening as it dries, plane the plank slightly hollow so that the ends meet first when clamping.

To minimise warping, alternate the direction of the grain in alternate planks.

Clamping is best done with some form of Bar/Sash/Pipe Clamp.

Use a minimum of three clamps.

There are other methods for ‘clamping’, you can even use a ‘Spanish Windlass’.

However, having at least three straight edges two below and one above will help ensure that the assembly glues up level.

Shaping something such as a bulkhead that must fit closely into an odd shaped space will need a pattern.

There are some tricks that can be used to create a pattern that will take account of compound curves, bent frames, futtocks and all the other irregularities.

The Tick or Joggle Stick.

Tick or Joggle Stick

Tick or Joggle StickThis is without doubt the most accurate and practical method for making any odd shaped pattern.

The 'stick' can be any old scrap timber preferably a stiff piece the length will depend on the shape you want to trace, for a bulkhead perhaps about a third of the beam of the boat.

Cut a point at one end and a couple of notches along the length, these are to make it easy to relocate the concise position of the stick later.

Next you need a scrap piece of reasonably stiff plywood.

This needs to be large enough to be tacked or clamped firmly, vertically along side the proposed position of the new bulkhead, this will be you 'pattern board'.

The board also needs to have a clean surface so you can draw on it with a pencil, a coat of white undercoat will give a perfect surface.

Now that you have that set up, with the stick flat on the 'pattern board' place its point at a position on the hull that you want to record and then trace the outline of the stick onto the 'pattern board' with your pencil.

You will need to be able to put your stick on to the trace in exactly the same position and same side up later, this is where the notches come it as reference points.

Repeat this for as many points as will be needed to create a complete profile of the hull shape including frames chain-plates etc.

Now take the 'pattern board' out and lay it on the panel that you wish to cut out.

Clamp it firmly to the panel.

Now take the same tick/joggle stick and place it onto those penciled outlines on the pattern, then mark the position of the point onto the panel.

Do the same for all the positions you have marked then join the points up with a spieling baton and straight edge.

Cut it out and hope it fits but don't expect the other side of the hull to be a mirror image.

Better to slap some more white undercoat on your pattern and do another trace for the other side.

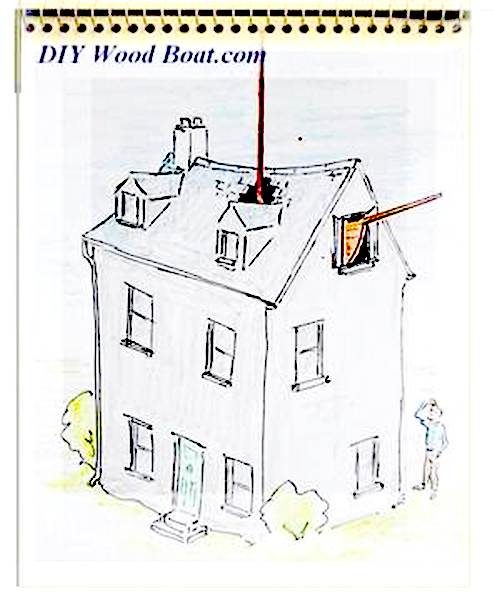

Drawing bow

Drawing Bow

Drawing BowIf you need to draw or work with a lot with curved parts a 'drawing bow' will allows you to lay out precise and large curves with only two hands.

This simple jig, a stick (spline) and a string, is easily made from a strip of wood that has straight grain through its thickness and width.

If the grain isn’t straight, you’ll get lumpy curves or the bow will break.

And a length of string, almost any string will do.

Drawing Bow End

Drawing Bow EndDrill a hole in one end of the drawing bow that is the same diameter as the string.

Thread the string through the hole and tie a knot in the string to secure it.

Drawing Bow for drawing an asymmetric arc

Drawing Bow for drawing an asymmetric arcAt the other end of the bow, first drill the same-diameter hole as earlier.

Then cut a 'V' that extends down the length of the bow, use a coping saw.

Thread the string through the first hole and knot its end to keep it in place.

To use the bow, bend the stick to the desired curve, then pull the other end of the string into the “V”-notch to pinch the string and hold the shape.

It is possible to draw an asymmetric arc by evenly tapering the thickness of the strip of wood.

affiliate links