- Home

- Your Boats

- Mast Boot

How to make a Mast Boot

A

mast boot,

skirt or coat is the traditional method for making a waterproof seal

between the deck and a keel stepped mast.

Despite modern advances in sealant technology, a flexible boot is still the most effective and best looking solution to preventing water leaking down the mast into the cabin.

A skirt is also a relatively simple, low tech, DIY solution, which can also be retrofitted.

Methods

It

is possible to simply caulk and seal around the wedges and partners but

this is unlikely to be very satisfactory and every time you need to

re-step the mast or adjust the wedges it will all have to be raked out,

and then resealed.

The next simplest method is to use a rigging and mast boot tape.

This is the self-amalgamating type of tape which can be bought in wide

rolls.

It is waterproof flexible and extremely simple to wrap on.

If that sounds too easy to be true, well it probably is.

First

it does need to be wrapped on to something, it is fine around the mast

and

wedges but getting it to cover the seam between the wedges and the deck

is the problem.

It will also show dirt and tends to peel after

time, and it isn’t all that cheap either, especially as you will need a

couple of rolls for the average mast diameter.

The next best DIY solution is the rubber mast boot.

These are made using inner tube material, if you can find any theses

days.

Wile

the inner tube and hose clamp system works well if done right it does

look pretty ugly and the rubber will degenerate over time in sunlight.

Another

option is to use a combination of the above methods, then

cover

with a wraparound cover of material such as ‘sunbrella’, which could

simply be attached with a ‘velcro’ strip.

But then if you are going to the trouble of cutting and sewing a cover why not make a proper mast boot in the first place.

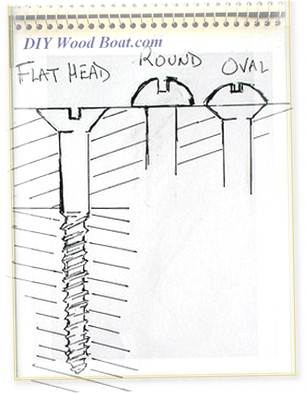

Fittings

The top of the mast boot attaches directly

to the mast.

The bottom edge will also need to be attached to something.

So you will need a deck ring or flange.

The

deck-ring should be well clear of the wedges and with a grove or lip

into which the bottom of the boot is securely fastened.

It will also be of the same profile as the mast, circular for a round mast, oval foe an oval mast and be positioned so as to allow the mast boot to have a runoff slope of somewhere in the region of 60 degrees.

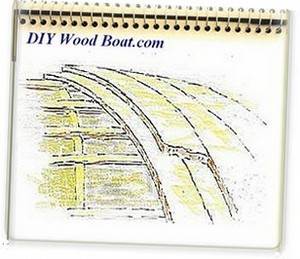

Making a Mast Boot Pattern

The material for a mast boot should be

strong, such as proofed

acrylic

or painted canvas.

The best mast boot requires three separate pieces.

The top and bottom collars will simply be cylindrical so they are easy

to cut and sew.

The middle part is the cone shaped bit, so that’s the tricky one to

measure out and cut.

It is always best to start with a paper pattern which can be tried

against the mast before cutting the material.

And perhaps even before buying material so you know exactly what you will need.

In

order to draw the pattern you will need to take note of three

measurements.

- The circumference of the mast.

- The circumference of the deck ring.

- And the proposed height of the mast boot from the deck ring to the top position on the mast. (H).

This height should allow for the finished boot to have a slope of at least 60degrees and be clear of wedges and any mast fittings.

This

is for a circular mast and deck ring, for masts and rings which are not

perfectly circular add a bit extra to the height (H) then trim the

pattern to fit.

Take these measurements and write them down.

So,

lets start with the top and bottom collars, these are added to smooth

the transition from the cone shape of the boot to the cylindrical shape

of the mast and deck ring.

The collars are simple oblong strips cut to the respective circumferences of the deck ring and mast with an allowance all round for sewing.

The

width of the deck ring collar needs to allow for any tuck around the

lip, one and a half times the deck ring height should be sufficient,

plus the hem.

The mast collar needs to be wide enough to take whatever means of

fastening you decide on.

Now the next stage is to work out that ‘lampshade shape’ for the main part of the mast boot.

I

have tried to do this just by pinning paper against the mast and trying

to do it free hand, believe me it is easier and quicker to do the

simple maths first.

So, first, we need to

work out the diameters

of the mast (Bd) and the deck ring (Cd), which if you remember your

geometry is the circumference divided by 3.1416 ().

Now we need to draw two arcs both with their centres at A.

But first we need to work out the length of their respective radiuses.

To get R2, multiply H by the diameter of the deck ring (Cd), and then divide by the difference between the diameter of the deck ring (Cd) and the diameter of the mast (Bd).

| R2 = | (H × Cd) |

| (Cd - Bd) |

At this stage it is always best to round any odd numbers up,

the paper pattern can always be trimmed down later.

To get R1 simply subtract the height (H) from R2.

The lengths of the arcs should be the respective circumferences plus a

bit for trimming/sewing.

Now,

cut out your paper pattern, take it to your mast, pin it or hold it

against the mast to check how it fits and trim as necessary.

Once

you are satisfied with the fit you can take the pattern to your cloth

and mark it out, not forgetting to allow plenty of extra for seams and

overlaps.

Sew the top and bottom collars on to the ‘lampshade’ and hem the top and bottom edges.

affiliate linksFitting

Ideally the whole mast boot would be sewn

up, the seams sealed and then

fitted to the mast before the mast is stepped.

However,

it can be fitted to an already standing mast, it just means that the

final sewing is a bit awkward, though the overlap can be done with a

good sticky sealant.

Begin by placing the boot inside out and upside down around the mast

and securing the top collar to the mast.

The very large sized hose clamps are ideal for this.

Don’t seal it just yet as the position may need to be altered.

Then pull the boot down over the top collar so that it reaches the deck

ring without being too tight.

Make sure that the overlaps are tucked inwards.

Secure the bottom edge to the deck ring temporally so you can check and

if necessary alter the fit.

Mark where you want the overlap to be sewn.

You

can now release the bottom edge to make sewing a bit

easier, it

is still going to be a fiddly job but well worth taking you time and

getting it as neat as possible.

You can then run some sealant down the seams.

You could just glue that side seam but the problem is how to hold the edges together wile the glue or sealant sets.

When

it is all sewn up and ready to go run some sealant under the top

collar, tighten up its fastening, pull the boot down and do the same

for the bottom edge.

Then all you need to do is paint or proof the mast boot or if you've used a waterproof cloth just run some sealant along the outside of the seams.

And you now have a relitively leak free Mast Boot.

affiliate links