- Home

- Your Boats

- Timber Properties

Timber Properties for Wooden Boat Building and Restoration.

There are several timber properties and mechanical characteristics that make wood such a superb material for boat construction.

This is just a general bit of background information on the properties of wood that I hope will help you to understand what a superb material it is.

It may help you chose lumber for your boat but unfortunately, unless you are lucky, you will not have the luxury of being able to pick and chose when you go to your local lumber yard.

Organic Timber Properties

Not only is wood a beautiful material to work with and behold

it is

also a naturally,

renewable resource.

It requires less energy to produce than many so called ‘modern’

materials.

And it isn’t plastic.

It

is the living tree’s ability to produce the material we know as wood

that is strong both in tension and compression, which enables them to

grow so large and remain upright.

And it is how it is cut and used that allows us to benefit from the timber properties of strength and ability to withstand various kinds of stress.

Not all species of timber are strong enough

for boat building.

And even within one species, different growth patterns due to environmental fluctuations can cause variations in quality.

Most

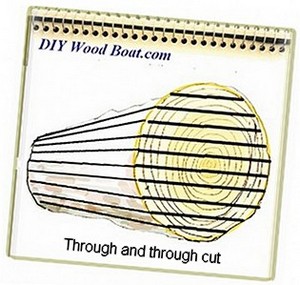

commercially obtainable wood is cut from the trunk of the tree.

And the way boards are cut from the log will affect how those timber

properties are utilised.

The stability and ‘figure’ of the wood will be determined by how it is

cut in relation to the grain of the wood.

Quarter

sawing produces the most stable boards, these will be cut so that the

growth rings are close to 90 degrees to the surface of the board.

However

the most economical, and therefore the most common method is to cut

parallel slices along the length of the log, this produces a few

quarter sawn boards but mostly a mixture of plain-sawn rift-sawn boards.

Most construction strength boards have the grain running along their length.

affiliate linksStrength, Stiffness and Elasticity

Wood

has several unique, independent mechanical properties.

However,

because of its cellular structure and the way in which these cell are

organised the strength of the timber is dependent mainly on the

direction of any loading.

The main strength is along the grain or up the height of the tree as it grows, this is the direction in which the cells and bonds between the cells grow.

The elastic

properties of wood are those which allow the wood to bend under load

yet return to normal once the loading has been removed.

It is this elasticity allows the timber to absorb and dissipate shock loads.

Strength

is usually regarded as the level at which it can be loaded before the

stress goes beyond the elastic range and failure occurs.

Stiffness is its ability to resist tension.

These timber properties do vary from species to species and even within

species due to environmental conditions during growth.

Much of the variation in timber properties is due to differences in

density.

Wood is composed of cells, pores and cavities between the cells.

The substance we call wood is in the cell walls.

It

is the variations in the ratio between the cavities/pores and in the

thickness of the cell walls which creates the differences in timber

properties.

Other factors that will affect the strength are defects

such as knots and shakes, moisture content and temperature.

Not all timbers are suitable for boat building.

affiliate linksWater content

One

reason we use dried or seasoned wood for constructional purposes is

that it increases those timber properties which affect strength..

The

greatest increase is its ability to withstand compression, and its

strength when under stress but without affecting the

elasticity unduly.

Generally, the greater the water content, the softer and more pliable

the wood will be.

This is part of the reason why steam bending works so well, the other

part being the hight temperature.

Steam bending can however weaken the internal structure of the wood.

Hardwood/Softwood

Timber is normally classified as either

softwood or hardwood.

It’s a method of classification that can be misleading as hardwoods are

not necessarily hard nor softwoods necessarily soft.

The wood from conifers such as pine is classified as

softwood.

Hardwoods on the other hand come mainly from broad leaved trees, such

as oak

This leads to such anomalies as balsa being classed as a hardwood,

while yew is classed as a softwood.

And even within a species there can be quite a range in the density of the wood it yields.

affiliate linksHeartwood/Sapwood and Color

The color difference between heartwood and sapwood in most species

does not generally mean that there is any difference in the mechanical

timber properties.

So much depends on the species, but generally the color difference is

just that.

Some

resinous species such as Longleaf Pine may show an

increase

in strength, due to the amount of resin which increases the

strength when it is dry.

There can also be a difference in

density, thus the hardness and strength and quality between latewood

and early-wood,

which shows up as a difference in color.

But

again there are so many different environmental factors involved as

well as differences in species and differences between ‘diffuse-porous

woods’ and ‘ring-porous woods’ that it is impossible to generalise.

Besides,

for ease of working, wood with straight grain and little in the way of

contrast between the latewood and early-wood is preferable.

Fortunately

for those of us who don’t have the luxury of being able to pick and

chose these differences are on the whole differences in degree.

And for the majority of us building or restoring small boats there will be more than enough of those desirable timber properties in the lumber we buy if we chose a suitable species and buy from a reputable lumber yard.

Previous posts

See What Others Have Posted

Can i replace a Mahogany plank with Iron wood, Maple, Ash, White Oak, or Birch?

I may need to replace a plank or two above and below the waterline of a 1967 Pacemaker 31 Flybridge Sedan Cruiser.

I have an abundance of trees, a …

Wooden Boat Frame

I would like to know what the best wood is for building the frame of a boat; dimensions approx. 75' x 21'.

Any input would be appreciated.

Thanks …

TIMBER QUALITY OR GRADING

What sort of timber quality or grading is required for keel timbers say 300 x 200 x 8.5 m long