- Home

- Boat Building

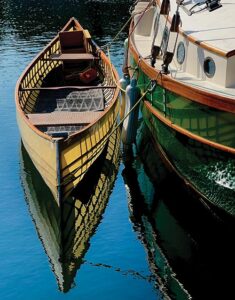

- Restoration

- Planking

- Bungs

- Bung Removal

Wooden Bung Removal

Wooden Bung Removal, some tips on how to clear those wooden plugs covering the fastenings when restoring or repairing a wooden boat's planking, decks or other joinery.

As well as keeping heads of fasteners covered for aesthetic reasons

bungs or plugs keep the heads of fastenings protected.

First locate and uncover bungs

Before removing a plank or any piece of joinery or trim it is necessary to find and remove all the fastenings.

And to access the screws means removing all the bung first.

If they have been inserted using shellac or putty then removal shouldn't be too difficult.

However if they have been glued in particularly if epoxy has been used then getting them out can be a problem.

If the plank or trim is going to be completely replaced then some damage to the surface isn't a problem.

But if you want to reuse the piece the last thing you need is damage to the edges of the bung hole.

It is always best to sand the area down to raw wood first, it makes finding the bungs easier and reduces the risk the edge of the hole splintering.

affiliate linksBung Removal, the Easy Ones

Most bungs should, unless epoxied, be removable like corks from a wine bottle.

As it's unlikely that you will be able to screw a corkscrew into them, you can get the same effect using an awl, unfortunately this will only work for the very easiest ones.

If that doesn't work the next stage of bung removal up is to use a woodscrew.

Drill a pilot hole in the center of the bung.

Screw in the woodscrew until its point bottoms out on the fastener.

Keep on turning the screw slowly and with a bit of luck the plug should start to ride up the threads.

Alternatively it may simply split the plug into a few pieces but these can easily be cleared.

Should a piece of the hole surrounding wood crack or chip out, glue it back in right away.

If the piece of joinery is to be reused and re-plugged, the hole will usually need to be cleaned out.

A chisel will usually be sufficient to clear the edges of the hole but care is needed to keep the sides of the hole flush and straight.

You can use a drill preferably a hand drill so you have more control and are less likely to cause damage.

However as long as any damage is not too severe you can always drill out a larger bung hole.

affiliate linksRemoving the Difficult Well Glued In Ones

Bung Removal for ones that are glued in solidly may require you to resort to using a Forstner drill bit and a chisel.

Forstner bits are designed primarily for cutting out flat-bottomed holes with very smooth sides.

However the cutting head has a very small center point so, to help start them centered use a center punch or awl.

Using a forstner bit that is smaller than the bung size, drill out the center of the bung.

Be careful to keep the drill at right angles to the surface so you go straight down the bung.

Go gently and stop as soon as the bit bottoms out on the head of the fastener, try not to damage either the bit or the head of the fastener.

It should now be relatively easy to clean out the remains of the bung with a chisel.

If you use an old or cheap chisel you can use this to clean any gunge out of the screw slot.

This is when you will be glad that a proper slotted screw was used.

Once the head of the fastener is exposed, there should be enough room to insert a screwdriver into the screw slot and carefully back the screw out.

Once the holes are clean you will be able to refasten the piece, insert new bungs and then refinish the wood.

Previous posts

See What Others Have Posted

Hardwood or softwood bungs?

What is the best timber for making wooden bungs?

Hardwood or softwood?

What timber is most effective and watertight?

This is for near the keel …